| Min. Order: | 1 Set/Sets |

|---|

Basic Info

Model No.: DHB-500-2

Process: Ferment

Additional Info

Packaging: wooden case

Transportation: Ocean,Land,Air

Port: Shenzhen,Dongguan,Hongkong

Product Description

2 vessel brewhouse craft beer brewing equipment

In this configuration, we use the following parametres:

Brew capacity: approx. 5hl / 500

Original wort: 11°Plato

Brewery yield: min. 75%

Brew cycle: 1 brew/day

4 days of brewing

1 day of cleaning

50 weeks/year

Fermentation/storage: 3 weeks, where

1 week of fermentation

2 weeks of maturation

Raw materials: 100% grinded brew malt

100% hop pallet

Part I 2 Vessel brewhouse DHB-500-2

For example,

This brewhouse is planned with a capacity of 5 hl / 500 L per brew cycle.

The whole brewhouse is mounted on a rigid rectangular frame, built from stainless steel.

It consists of 2 vessels:

· Mash and wort kettle

· Lauter vessel and whirlpool, which is placed underneth the lauter vessle and used

during lautering as the first running pot

Between the brewing kettles, there is a stage mounted. In the back part of the unit the control panel is mounted with the control and feedback devices.

Underneath, the piping with valves and the mash and wort pumps are mounted.

The brewhouse can be ordered in serveral stages:

· Manual Operation:

All valves are operated directly on the valves. In this case the piping is built, that the operation is comfortable for the operator.

All motors will be started by switches on the control panel.

The temperature control is done by a simple temperature controler without timing control.

· Partly automated operation:

All valves will be operated directly on the touchpanel (only manual-mode).

The valves are positioned, that they are easily accecable for the operator.

The motors will be switched on the control panel manually.

The temperature control is done by a simple temperature controler without timing control.

· Partly automated mashing and brewing operation:

Additionally to the partly automated operation, the mashing and wort cooking is done fully automated.

· Fully automated control

All valves can be controlled manually on the touchpanel, alternatively complete steps will be controlled automatically.

As example the mashing or wort cooking can be named.

Motors will be started on the touchpanel or automated through the program.

Control Panel

Optional for additional charge:

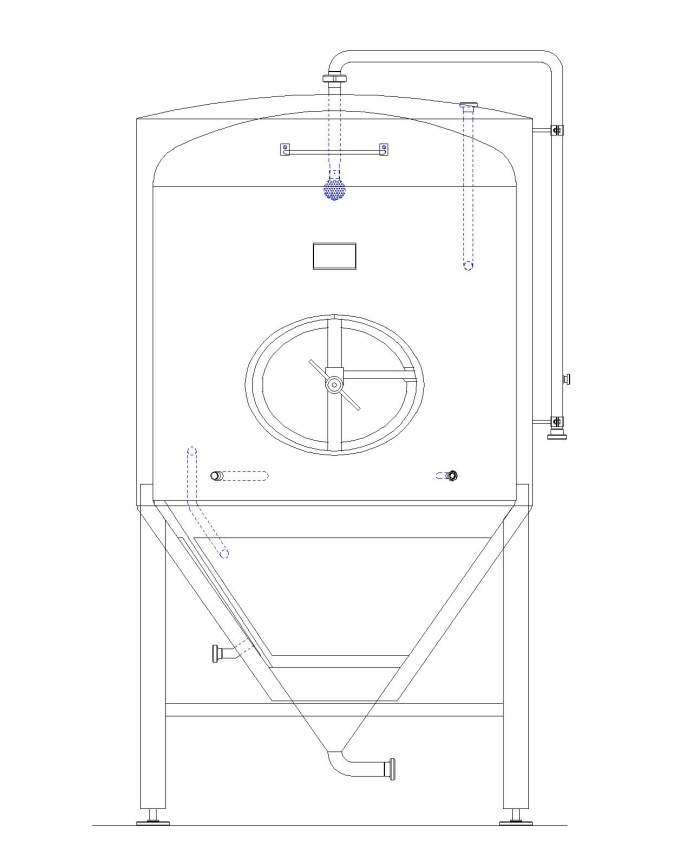

Part II. cylindrical-conical fermentation and storage tanks with a capacity of 5 hl

equipped with:

each tank is equipped with:

Part III. Hot water tank 10hl

Part IV. Malt Mill

Part V. Steam generator

Part VI. Cooling plant – Glykol for wort and vessel cooling

Optional equipment:

· partly automated control

consisting of:

· Splash water resistant electrical cabinet

· Touch screen display

· VIPA or Siemens S7 PLC with Touch-Screen

· Temperature sensors PT100

· Temperature controller

· Visualization of the brew process

· Fault analyzing

· With pneumatic valves in the piping

All medium valves will be controlled on the touch panel (only manual function), whereas the piping is built for a convinient use of the valves.

Motors will be switches on the control panel.

The temperature control of the brew is regulated by a simple temperature controller without time control.

· Partly automated control with mash and brew automation

Consisting of:

· As partly automated control

· Visualization of the the brew process

· Input of recipes and fault analyzing

All medium valves will be controlled on the touch panel (only manual function), whereas the piping is built for a convinient use of the valves.

Motors will be switches on the control panel.

The temperature control of the brew is done automatically.

Brewhouse fully automated - Consisting of:

· As partly automated

· Visualization of the brew process

· Input of recipes and faul analyzing

· With eletronic sensors and signalization devices

· Flow meter to control the lautering speed

Temperature control for each tank

Polished copper hoods in traditional bavarian design with chimneys

· 2x copper hoods

· 2x panels

· 2x chimney

· 2x man holes

· 2x sight glass

Brewery example:

CONTACT US

Dongguan Deao Food Equipment Co.,Ltd

Contact Person: Darwain Wang

Phone:86-0769-82868162

Fax:86-0769-82868162

Address: Shanglin industry park, Hengli town, Dongguan,Dongguan,Guangdong